LEARN ALL ABOUT LASERS 1-10

Laser show projectors in the entertainment industry

The content of this page provides general information and subjective opinions of the various content contributors and is designed for informational purposes only.

01.

What is a LASER?

The laser is a bunch of energy waves (streams of photons called radiation) with the same amplitude and phase flowing in the same direction, meaning they are coherent - they stick together and form a laser beam.

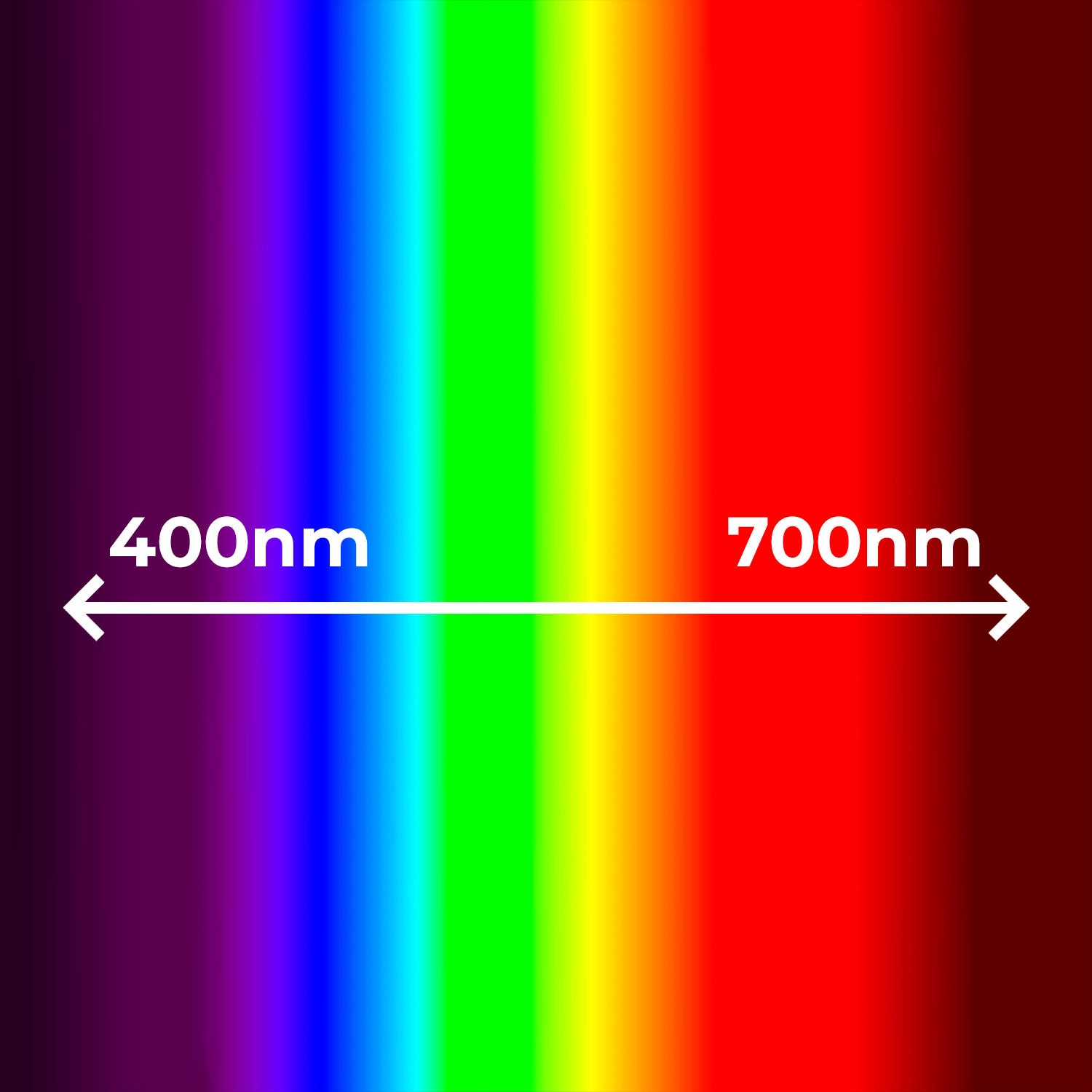

The width of a single wave is measured in nanometers and defines the colour and visibility of the laser beam.

The visible spectrum of light is in the range of 400 - 700nm

02.

What makes the laser beam and effects visible?

Mainly, it is the particles of dust and water in the air that the laser beam hits on its path.

We "laserists" use haze or smoke machines to make lasers more visible. Too much of the haze or smoke will kill it, but the right amount will make all the difference between no!show and a great show.

When outdoors, lasers mainly reflect off dust and mist in the air, but due to unpredictable wind conditions, we can never make sure the hazers or smoke machines will be effective enough. And that's why we use high-power lasers for outdoor shows - to substitute for the lack of dust, haze and smoke.

03.

How far does the laser go, and can it get to the Moon?

Depending on the power output of the system and weather conditions, the laser can be visible for miles - that is why we need to be cautious about aircraft when performing outdoor shows.

And if you get a system that is powerful enough, then YES, it can reach the Moon. A laser is a form of light, and unless stopped, it travels infinitely.

This is us, shooting into the space.

04.

How do the laser colours work?

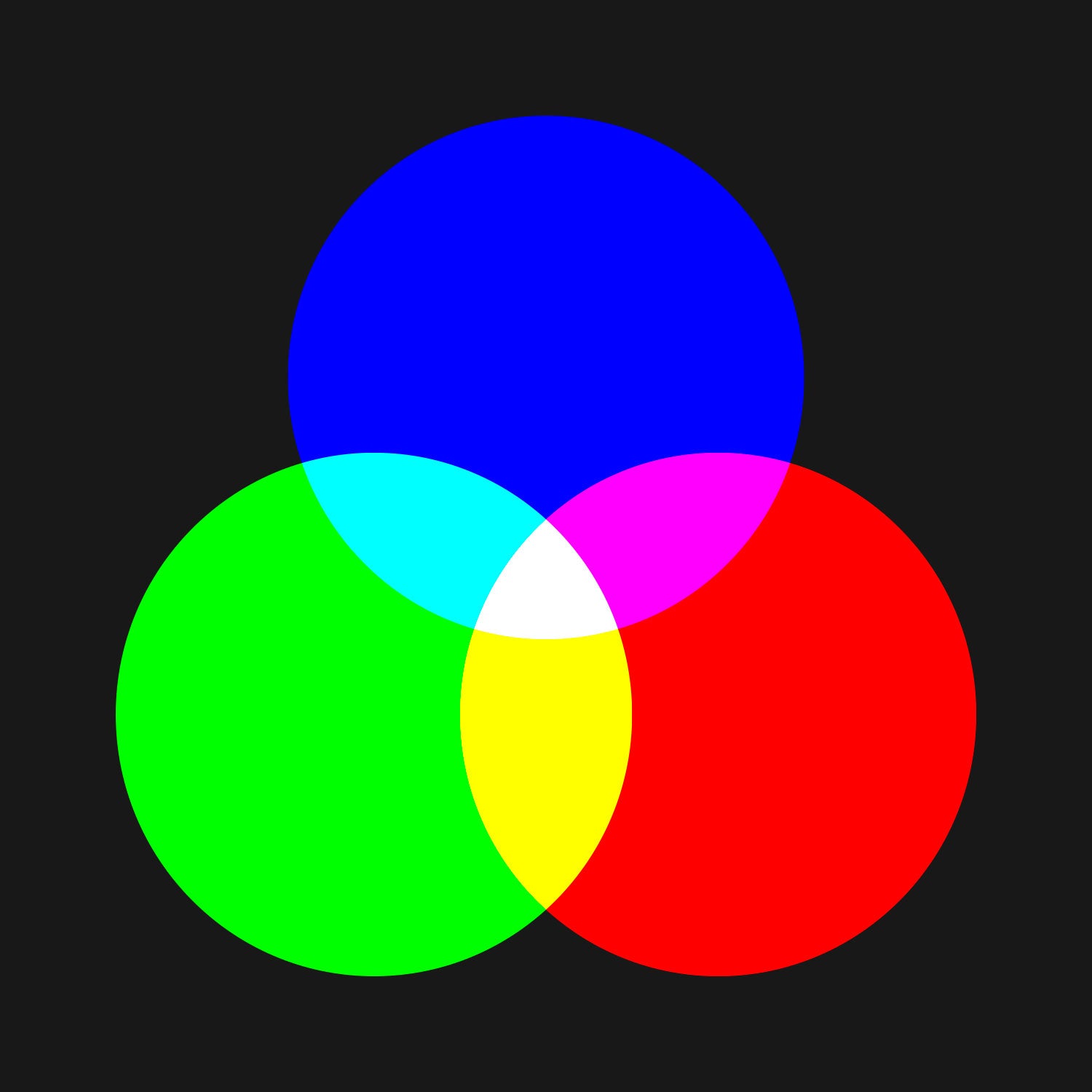

Standard full-colour analogue lasers use three primary colours: Red, Green and Blue. By mixing those, you can get any secondary colour.

Red + Blue = Magenta

Red + Green = Yellow

Green + Blue = Cyan

Red + Green + Blue = White

Of course, the number and precision of the colours are determined by the stability and linearity of the system's modulation. If the system is not stable enough, it will produce different colours every time, making it virtually impossible to match the colours of two systems at one time - there are tons of these crappy ones on the market, so be careful.

Isn't it strange that mixing red, green and blue generates white?

05.

How do I recognise a quality laser projector?

You will only if you are experienced.

We recommend you to do some research. The online forums and other people's references are probably the best for that. In general, the laser market is one of those where you get what you pay for, and there's no way around it.

The quality will always cost you a fair bit of money, but even then, you need to make sure you are getting the quality you pay for.

This KVANT Spectrum projector is one of those where the quality is unquestionable. Yep!

06.

The main factors that determine the quality.

Laser source technology and quality of build

Anyone can bolt some components together, but building a quality and long-lasting laser takes a lot of precision and experience, and that's the issue here.

It is quite likely, though, that long-established manufacturers who do have facilities for their own development and manufacturing will do their job well. We recommend you be careful, though. Some companies are only in it for quick money.

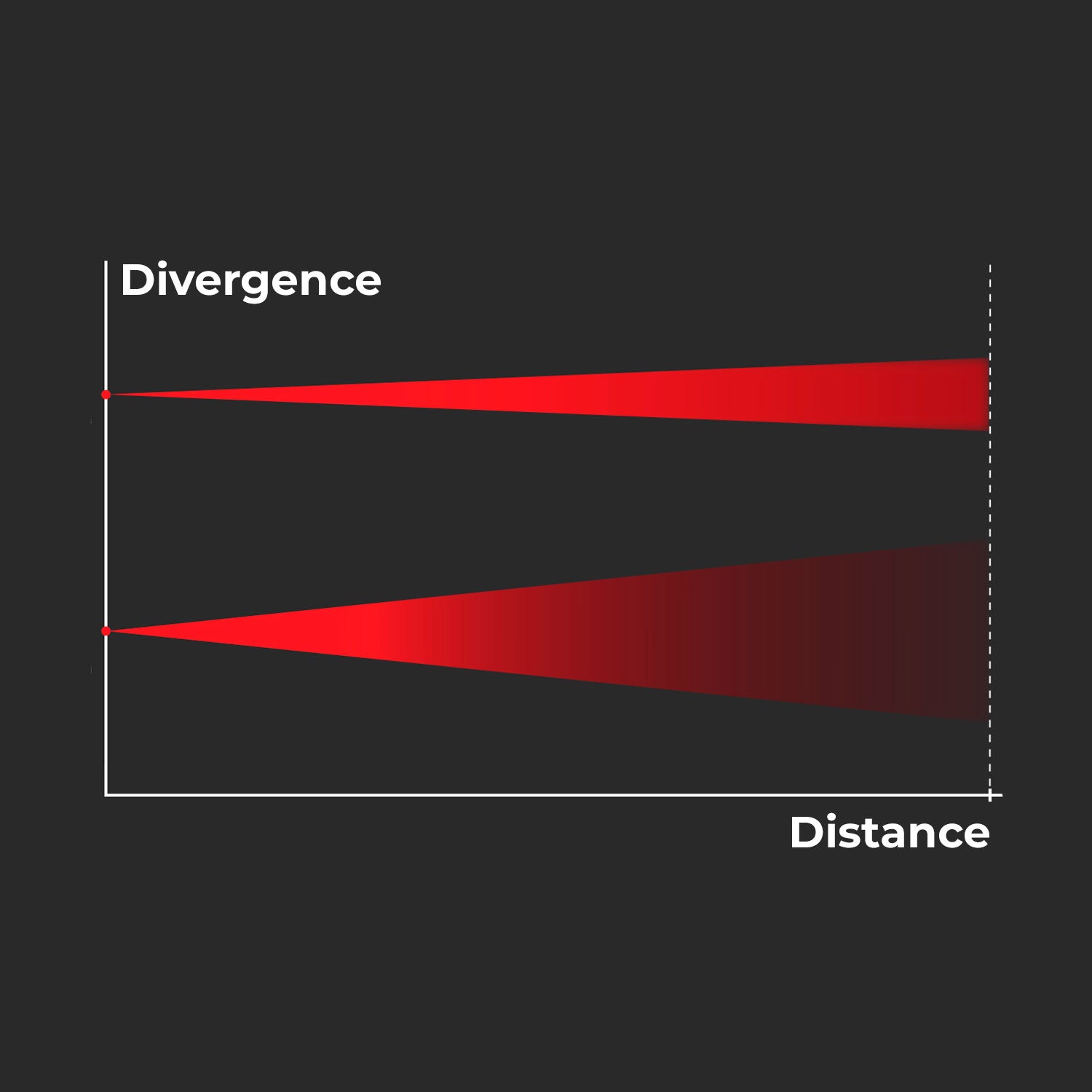

Size of beam and divergence

The smaller and tighter the beam is over a distance, the better visibility you will get. This is a general rule that applies to a certain extent. If the beam observation distance exceeds human eye resolution, thicker beams will work better.

Also, matching beam sizes and beam profiles of all the colours are very important when it comes to full-colour lasers. If the beams don't match each other, you will see all kinds of halos around some mixed-colour beams.

More power with a broader spread doesn't mean more brightness over distance.

07.

What is a modern laser display projector made of?

Housing - these days, it can get pretty sophisticated and IP-rated with many clever and useful features for touring and dry hiring.

Laser source - quality laser modules are essential for reliable, decent performance and a long system lifespan.

Scanning system - the scanning speed and precision determine the graphical performance of the system.

PSU - if this fails, everything else fails too. We use only quality power supplies with low failure rates.

Driving electronics - there's a great deal of development going into the driving electronics as the laser modules' performance heavily depends on the quality of its driver board and temperature stabilisation technology.

Safety features - these are firmly established by law but very often ignored. Ensure your system is up to date and legal to use; otherwise, you are risking a lot!

Optical components - non-quality optics can get damaged by the heat of the laser source; this, in turn, will cause significant losses in power and/or misalignments.

Connectors, Cables, Fuses, bits and pieces - all of these are critical. What difference will a good-quality laser make if you use poor-quality signal cables? NONE.

We found foamed aluminium to be quite an interesting and practical material to use for manufacturing laser projectors.

08.

Scanners - how do they work?

A scanning system comprises two motors with tiny mirrors, each moving the laser beam on the X or Y axis. Working together, they "scan" the laser beam in any forward direction within a certain spread - usually between 40 and 60 degrees on the X and Y axes.

Once a shape is scanned more than 20 times per second, it starts to appear static to the human eye.

So, any shape drawn by a laser is produced by one laser beam running around like crazy.

Every scanning system has a mechanical limit of how many points it can display at any time, usually represented in Points Per Second (pps) or Kilo Points Per Second (kpps), for example, 30 kpps.

Cone or Tunnel effect explained:

If you make a single laser beam "scan" a circle fast enough, you will see a static circle on the wall. However, when you turn around to face the laser, you will stand in a cone of light.

Not only speed but also drawing precision and heat dispersion capability are of the same importance.

09.

ILDA laser or 3D laser?

ILDA is an acronym for International Laser Display Association, but it also represents standardised laser signal protocol still used by many low-cost and consumer-level laser manufacturers.

The fact that a laser is ILDA-compatible (meaning you can control it from any ILDA-compatible control system) does not give you any quality assurance. Even the cheapest and worst lasers can be "ILDA".

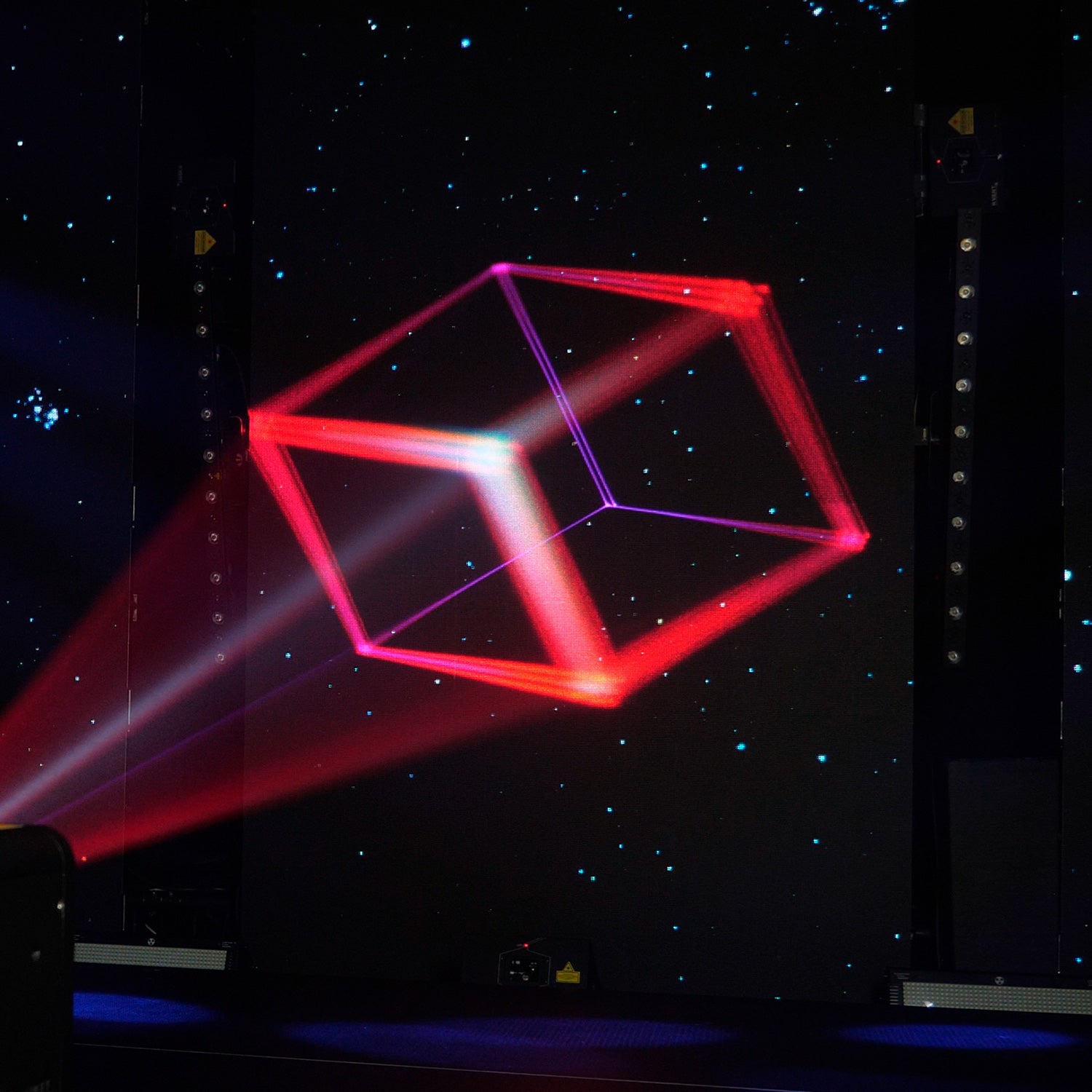

3D lasers are a myth and part of marketing tricks.

Any laser can create 3rd dimension by projecting into a space. Lasers can have various additional effects mounted for different purposes, but those have hardly anything to do with 3D projection.

This looks pretty 3D, doesn't it? Calm down; it's just an illusion.

10.

Laser control systems.

There are a few control systems on the market to choose from, and the overall performance of a laser system is heavily dependent on the quality of the control system you use, so don't hesitate to invest a fair amount of money into it.

Professional lasers and shows must be under proper control!